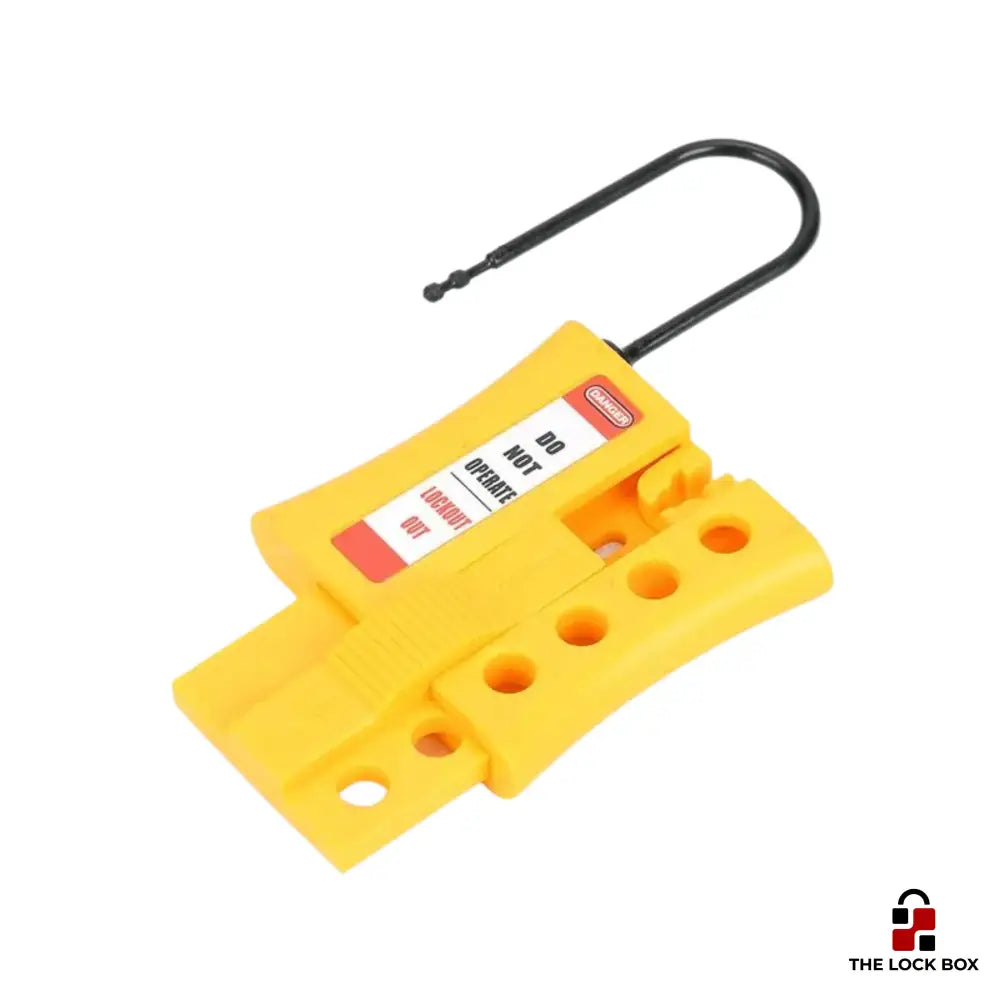

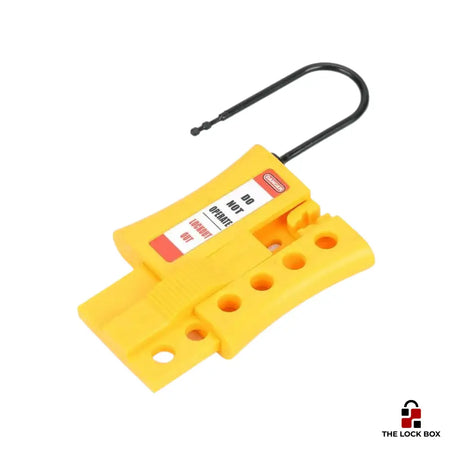

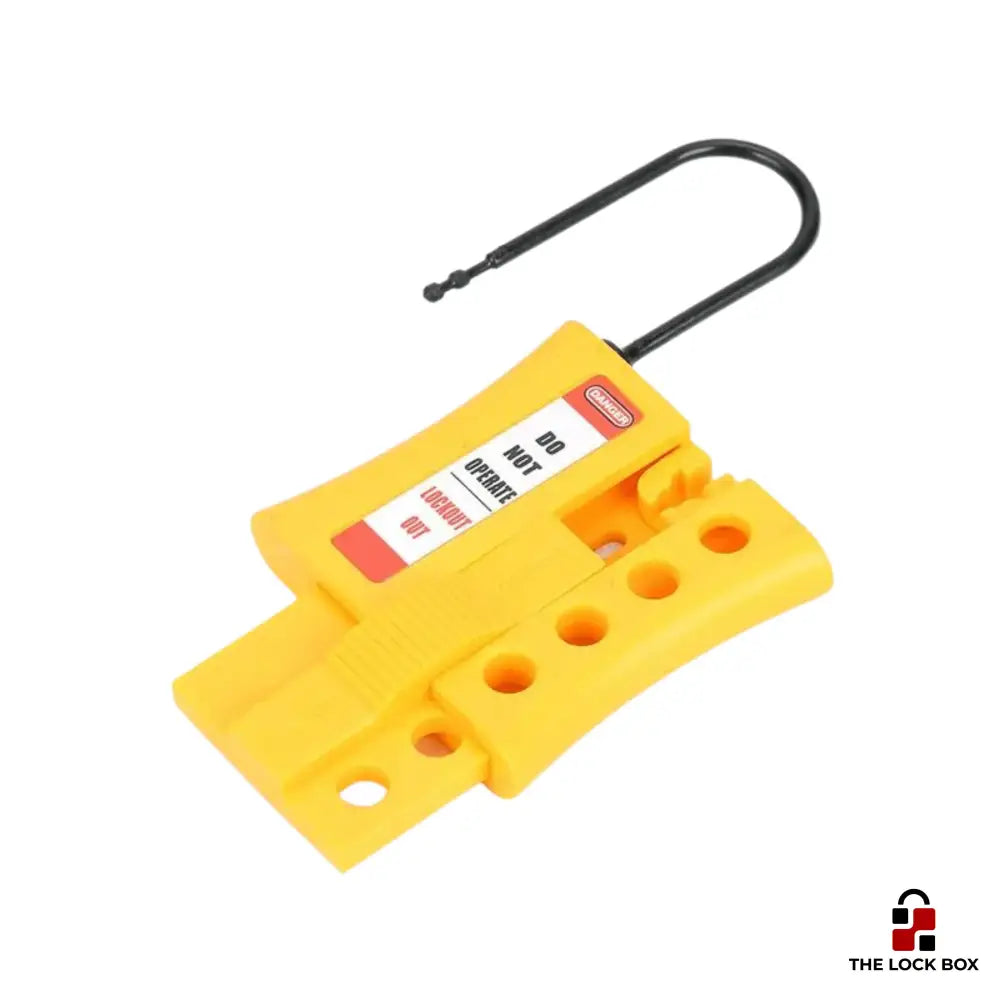

Nylon Safety Hasp - LOTO Padlock - Thin

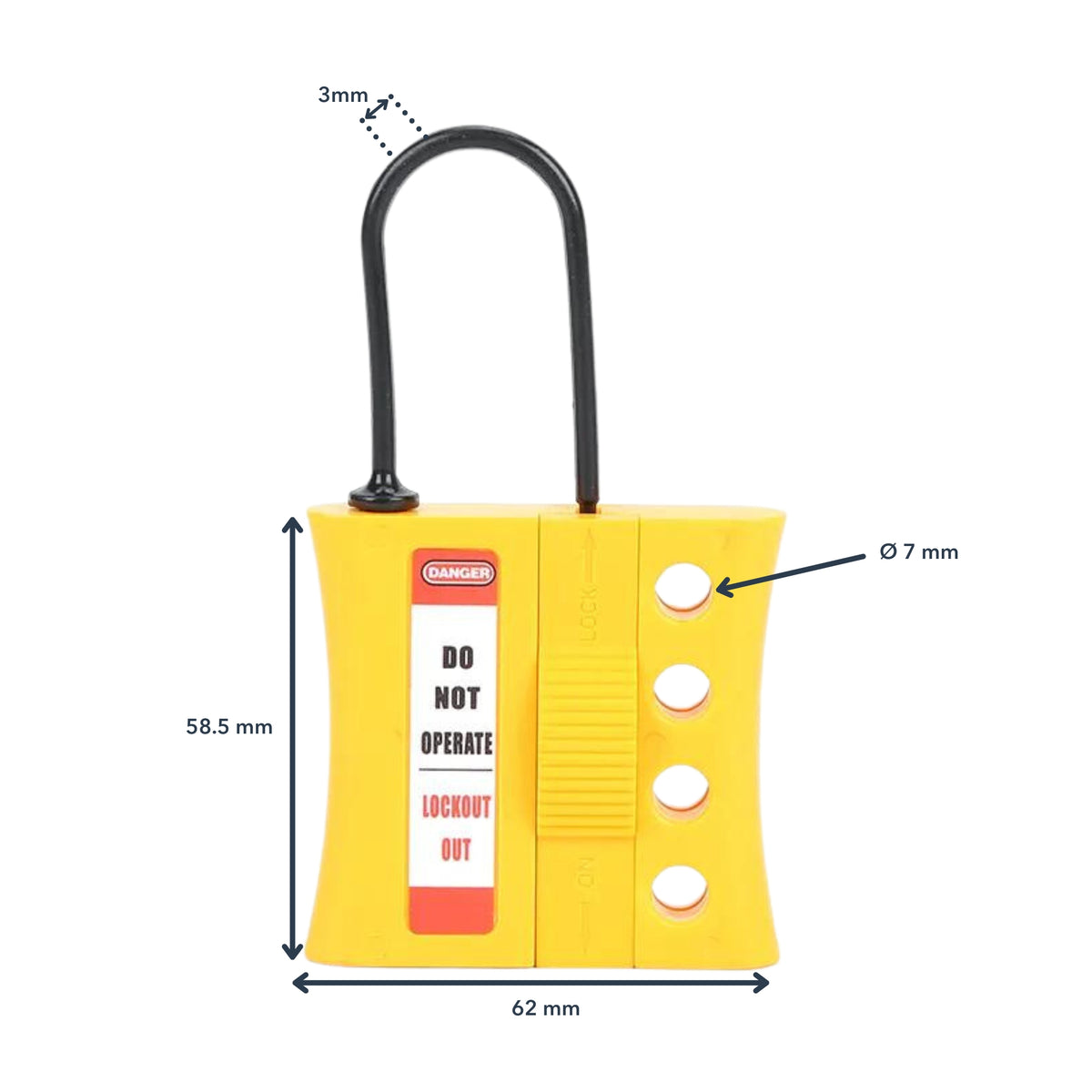

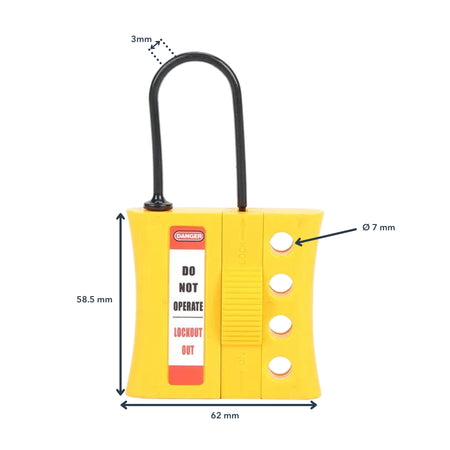

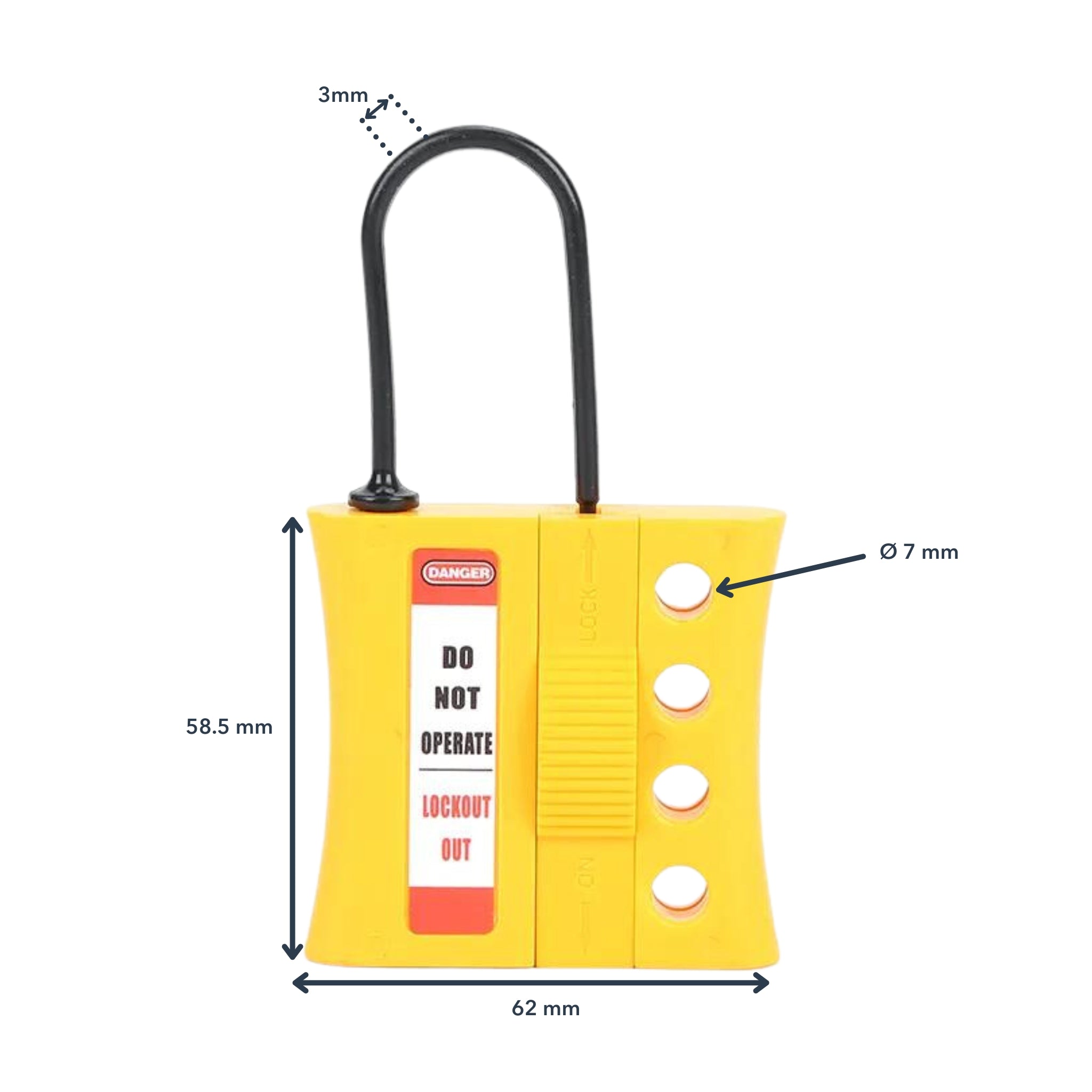

Fits 4 padlocks

Designed to be non-conductive and corrosion resistant.

Want a customised solution, samples or to order in bulk? Reach out to our experts at hello@thelockbox.ch.

Regular price

CHF 24.99

Insulated yellow safety hasp, with thin shackle. Designed specifically for applications where multiple locks are required at a single isolation point.

| Color: | Yellow |

| Dimensions L x W: | 105mm x 62mm |

| Lockout Points: | 4 |

| Material: | Nylon / Durable ABS Plastic |

| Shackle Width: | 3mm |

| Usage: | Chemical, Food & Beverage, Pharmaceutical, Water Utilities |