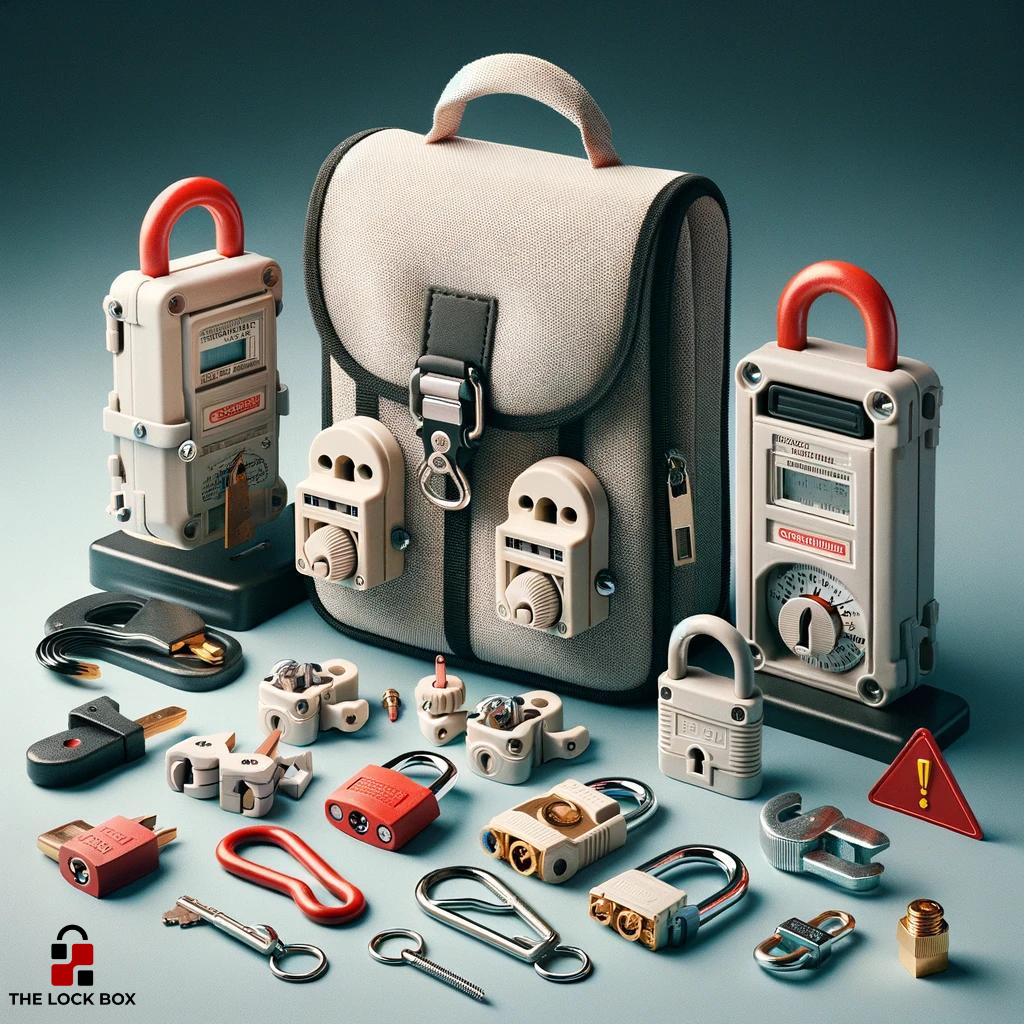

In industrial safety, the significance of a well-equipped Electrical Lockout/Tagout (LOTO or LOTOTO) kit cannot be overstated. Lockout/Tagout procedures are critical for safeguarding employees from electrical hazards during maintenance or repair activities. In this post we'll take a look at what components that constitute an effective Electrical LOTO kit, aimed at ensuring workplace safety and compliance with regulatory standards.

Understanding Electrical LOTO

Electrical LOTO procedures involve the systematic shutdown and isolation of electrical energy sources to prevent accidental or unauthorized energization of electrical equipment. The process safeguards maintenance personnel from electrical shocks, arc flash incidents, and other potential hazards, thereby fostering a safe working environment.

Core Components of an Electrical LOTO Kit

Below is an outline of the typical items which can be included in Electrical LOTO kit:

Lockout Devices for Circuit Breakers

Circuit breakers, pivotal in managing the flow of electrical energy, necessitate secure lockout devices to maintain the "off" state during maintenance operations. The Lock Box offers specialized devices for different types of circuit breakers:

-

Pin Out Standard Lockouts: Designed for circuit breakers with outward-facing pins, these devices feature a push-button mechanism that facilitates easy and secure attachment. By locking the breaker in the off position, they prevent inadvertent re-energization, ensuring a safe maintenance environment.

-

Pin In Standard Lockouts: Tailored for breakers with inward-facing pins, these lockouts ensure a firm and secure lock, effectively neutralizing the risk of accidental switch-ons. The simplicity of their design allows for quick application and removal, streamlining the LOTO process.

-

Pin Wide Standard Lockouts: Ideal for breakers with perpendicular outward-facing pins, these devices provide a broad coverage, ensuring that the breaker's switch remains inaccessible during maintenance tasks. Their robust construction guarantees durability and long-term use.

-

Universal Electrical Miniature Circuit Breaker Lockouts: For atypical circuit breakers that don't conform to standard designs, The Lock Box offers a universal solution. These versatile lockouts can adapt to various sizes and configurations, making them a staple in any Electrical LOTO kit.

Lockout Devices for Disconnect Switches

Disconnect switches require lockout devices that can accommodate their unique designs. The Lock Box's solutions for these switches ensure that they are securely locked in the "off" position, eliminating the risk of accidental energization:

- Clamp-On Lockout Devices: These devices are designed to encapsulate the entire switch, providing a comprehensive lockout solution that leaves no room for inadvertent activation. Their adjustable design allows them to fit a wide range of switch sizes, making them an indispensable tool in electrical safety.

Electrical Plug Lockout Devices

To prevent electrical equipment from being inadvertently powered, The Lock Box offers lockout devices that isolate plugs from their power sources:

- Electrical Plug Lockout Boxes: These boxes encase electrical plugs, rendering them inoperable and ensuring that equipment remains de-energized during maintenance. Available in various sizes, they can accommodate most plug types, providing a versatile solution to electrical lockout challenges.

LOTO Signage Tags

To complement the physical lockout devices, kits should also include LOTO Signage Tags. These tags serve as a critical communication tool, providing essential information about the lockout procedure, including the reason for the lockout, the identity of the person who applied the lock, and their contact information. The tags are designed for high visibility and durability, ensuring that the lockout message is clearly communicated to all personnel.

LOTO Padlocks for Lockout of Equipment

Kits should also include Padlocks preferably made from steel or nylon depending on requirements. These padlocks should be each keyed differently to maintain individual control over lockout points. Padlocks should be designed to withstand harsh industrial environments, ensuring long-lasting performance and reliability.

Hasps

The safety hasp, should be robustly designed and have a durable nylon body. Its A 25mm or 38mm diameter allows for ample space to accommodate multiple padlocks, ensuring that the energy source remains securely isolated until every authorized personnel has completed their task and removed their lock. This collective approach reinforces the principle of safety in numbers, preventing any premature re-energization of the system.

Advantages of Using an Electrical Lockout/Tagout Kit

The implementation of an Electrical Lockout/Tagout (LOTO) when utilized effectively, can significantly mitigate the risks associated with electrical systems, thereby ensuring the safety and well-being of personnel. Here are some of the key advantages of using an Electrical LOTO kit in the workplace:

Enhanced Safety

The paramount advantage of employing an Electrical LOTO kit is the substantial enhancement of workplace safety. By isolating energy sources and ensuring equipment is de-energized, LOTO kits protect maintenance personnel from electrical shocks, burns, arc flash incidents, and other potentially fatal accidents. This proactive approach to safety helps in creating a secure environment, fostering a culture of caution and care among the workforce.

Regulatory Compliance

Adherence to safety regulations such as those enforced by OSHA in the United States, the European Union's Directive 2009/104/EC, or other local safety standards is crucial for any business operation. An Electrical LOTO kit ensures that organizations meet these regulatory requirements, thereby avoiding legal complications, fines, and potential shutdowns. Compliance also demonstrates a company's commitment to maintaining industry best practices and upholding a high standard of safety.

Prevention of Equipment Damage

Beyond protecting human life, Electrical LOTO kits play a critical role in safeguarding equipment from damage. Unintended energization or improper handling during maintenance can lead to equipment failures, costly repairs, or the need for complete replacements. By securing equipment with LOTO procedures, businesses can prevent these incidents, ensuring the longevity and reliability of their machinery.

Minimization of Downtime

Electrical accidents can lead to significant operational downtime, disrupting production schedules and leading to financial losses. By effectively implementing LOTO procedures through comprehensive kits, organizations can minimize the risk of such accidents. This proactive safety measure helps in ensuring that maintenance tasks are completed efficiently and safely, thereby reducing unnecessary downtime and maintaining productivity levels.

Increased Awareness and Safety Culture

The routine use of Electrical LOTO kits fosters a heightened awareness of safety practices among employees. It instills a sense of responsibility and vigilance, encouraging workers to always prioritize safety in their operations. This increased awareness contributes to building a strong safety culture within the organization, where safety becomes a shared value and priority among all team members.

Versatility and Adaptability

Electrical LOTO kits are designed to be versatile and adaptable, capable of addressing a wide range of electrical lockout scenarios. Whether dealing with circuit breakers, disconnect switches, or electrical plugs, these kits provide a comprehensive set of tools to ensure the safe isolation of energy sources. This adaptability makes LOTO kits an indispensable asset in diverse industrial environments.

Employee Empowerment

Providing employees with the tools and training to perform lockout/tagout procedures empowers them to take control of their own safety and that of their colleagues. This empowerment fosters a proactive approach to workplace safety, where employees are actively engaged in identifying potential hazards and taking the necessary precautions to mitigate risks.

Standardization of Safety Procedures

Electrical LOTO kits standardize safety procedures across the organization, ensuring that all employees follow a consistent and effective approach to energy isolation. This standardization eliminates confusion, reduces the likelihood of errors, and ensures that safety practices are uniformly applied, regardless of the department or individual performing the maintenance task.

Long-Term Cost Savings

Investing in a comprehensive Electrical LOTO kit can lead to significant long-term cost savings. By preventing accidents and equipment damage, organizations can avoid the costs associated with medical treatments, legal fees, equipment repairs, and lost production time. The initial investment in a quality LOTO kit pales in comparison to the potential financial and human costs of electrical accidents.

Enhanced Reputation

A strong commitment to safety, demonstrated through the use of Electrical LOTO kits, can enhance an organization's reputation. It signals to employees, customers, suppliers, and regulatory bodies that the company takes safety seriously and is dedicated to protecting its workforce. This positive reputation can lead to increased employee retention, customer trust, and business opportunities.

The Lock Box's has designed specific lockout tagout kits to mitigate electrical hazards in industrial environments, enhancing workplace safety. From circuit breaker lockouts to plug isolation devices, each product is crafted with user safety and convenience in mind. Explore the full range of Electrical LOTO solutions at The Lock Box's Electrical Lockout/Tagout Collection.